If you own an industry that works with the extrusion of metals, then your main concern lies with selecting alloys like brass, bronze duralumin or 6061 aluminium.

However, why do we need this alloy is a question to ask. As we know, all the different pure metals like steel, aluminium etc., have fixed properties. This means that they will have a permanent amount of strength, durability, malleability melting points and attributes. Whereas when two or more pure metals are mixed, they form a hybrid element such as copper, 6061 aluminium alloy etc. Moreover, the new blends of metals formed possess the properties of all the pure Metals used in extrusion. This makes the alloy formed stronger, extra durable, and flexible, ideal for a specific purpose. Moreover, when the aluminium alloy is made, it becomes as strong as Steel which also means if you are thinking of using 6061 aluminium alloy in making strong products, it will be worth it.

Knowing aluminium alloy little more

It is the most commonly extruded alloys and holds its history for decades. It was first made in 1935 and was known as “Alloy 61s”, but now it is either referred to as 6061 Aluminium Alloy or structural aluminium. This name suits it because of its defining properties, making it ideal for use in many applications like building products, piping, electrical fittings and leisure products.

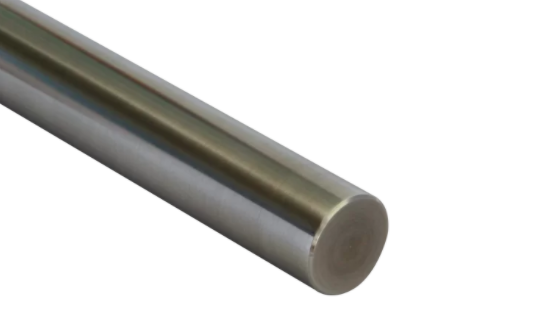

The 6061 aluminium alloy is a wrought alloy, which makes it extruded, rolled or forged into a variety of shapes smoothly and hard as steel. Then there is casting alloy, which can be cast in the sand or poured into molds to give them some desired shapes.

The 6061 aluminium alloy consists mainly of aluminium, magnesium and silicon. There are many other metallic elements present in it with less amount, including iron, copper chromium, zinc, manganese and Titanium.

Common characteristics of 6061 Aluminium

This alloy’s set standard in terms of strength, economical material, and lightweight rise from medium to high.

It has a good surface finish and toughness too. It possesses a property that is its resistance to corrosion from both atmosphere and seawater. Earlier alloys were vulnerable to corrosion, but aluminium alloy has some chromium, which makes it corrosion-free. This alloy’s main chemical composition is magnesium, which is used to increase its strength, and silicone helps reduce the melting temperature of the metals. Its manufacturability and ability of it to be easily welded and joined make it more accountable. The chemical composition of 6061 aluminium alloy makes its welding easy, but it may lose some strength during the process. However, it can be reheated and aged unnaturally again to restore its strength, making it a top-quality alloy.

What are the various uses of 6061 Aluminum?

- The 6061 alloys have become an inevitable part of our lives, whether it’s for making construction or manufacturing materials.

- It is used to manufacture automotive parts weather for your yacht, motorcycles, bicycle frames, automobiles, scuba tanks, camera lenses, fishing reels, electrical supplies and fittings.

- It is also used for making aluminium cans, bottles and more.

- You will also find its use in the making of food containers and foils to wrap edible stuff.

- The 6061 aluminium is also used to construct roof structures for bridge decks, stadium covers and arenas.

- This tough alloy is also used to produce solid and hollow shapes that are either customized or standard type.

- It is also great to make rod and bar products and other structural pipes and tubes.

Different types of alloys

The 6061 aluminium is the most common and widely used alloy, but there are few more alloys which are such as-

- 7075 aluminium alloyed with zinc.

- 6063 aluminium is best for making railing or trim windows and doors.

- 5052 aluminium has magnesium, primarily making it weldable.

- 2024 aluminium has copper mainly, which is used in making wings and fuselage of aircraft.